Advantage

High thermal conductivity material (conductivity:13.5 W/mK) is 25 times better than traditional resin (conductivity: 0.54 W/mk).

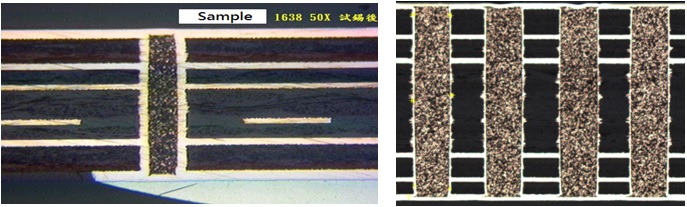

Hole insertion process: Vacuum screen printing

- Through hole insertion: deepest 6.0 mm, aspect ratio large than 1:40.

- buried hole insertion: deepest 0.15mm, aspect ratio large than 1:1.

- Surface flatness: no convex, cave < 10um.

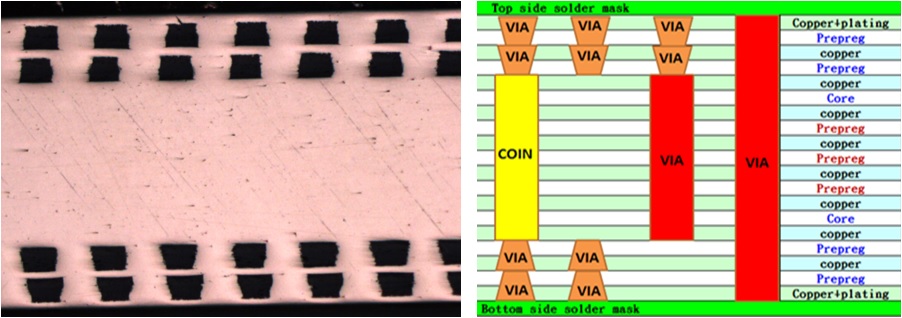

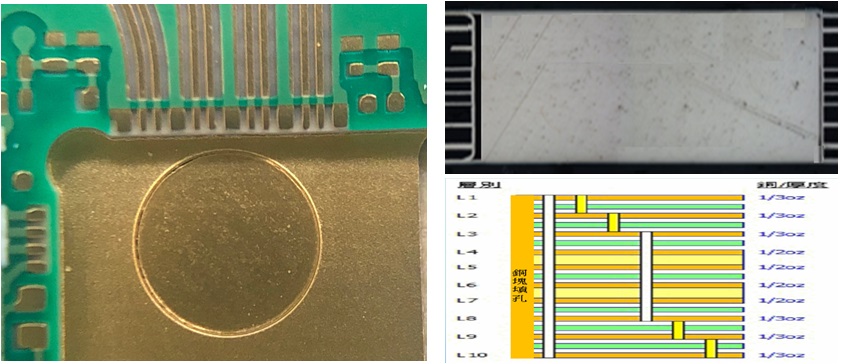

To reduce temperature & enhance high power component performance, copper block will embed below component which benefits heat source conducted to another side via copper column.

Coin Insertion Technology

Slotting at same position after inserting copper block below coin.

1. Cavity the depth to reach copper block.

2. No cavity but placing high power component inside

the slot.

Make heat source conducts to ground via copper block.